Description

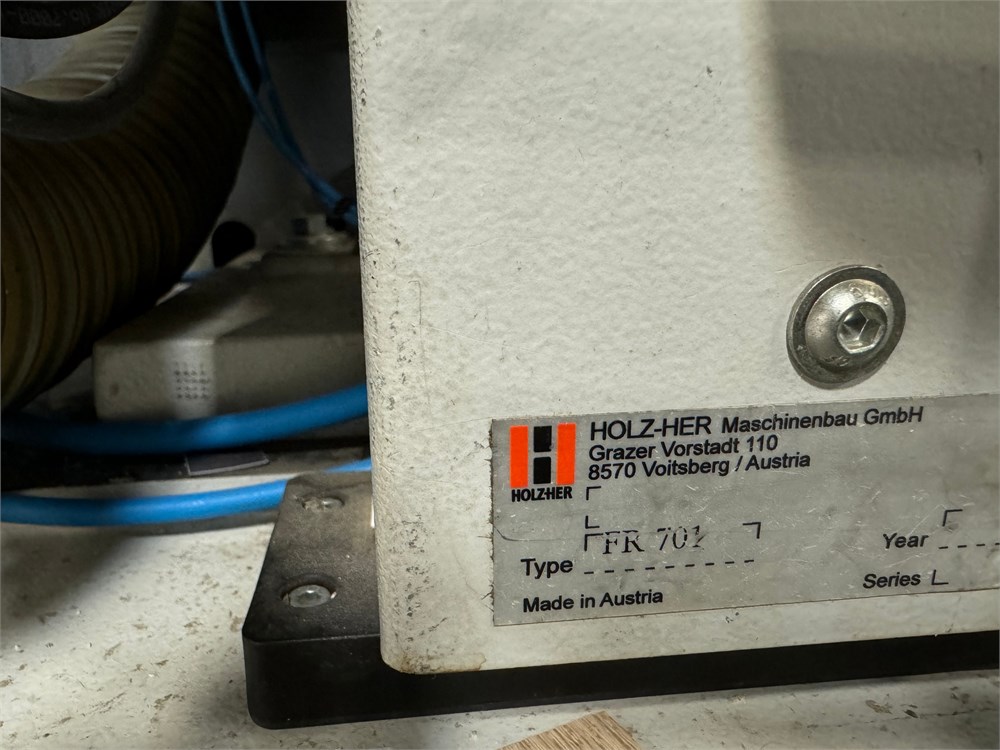

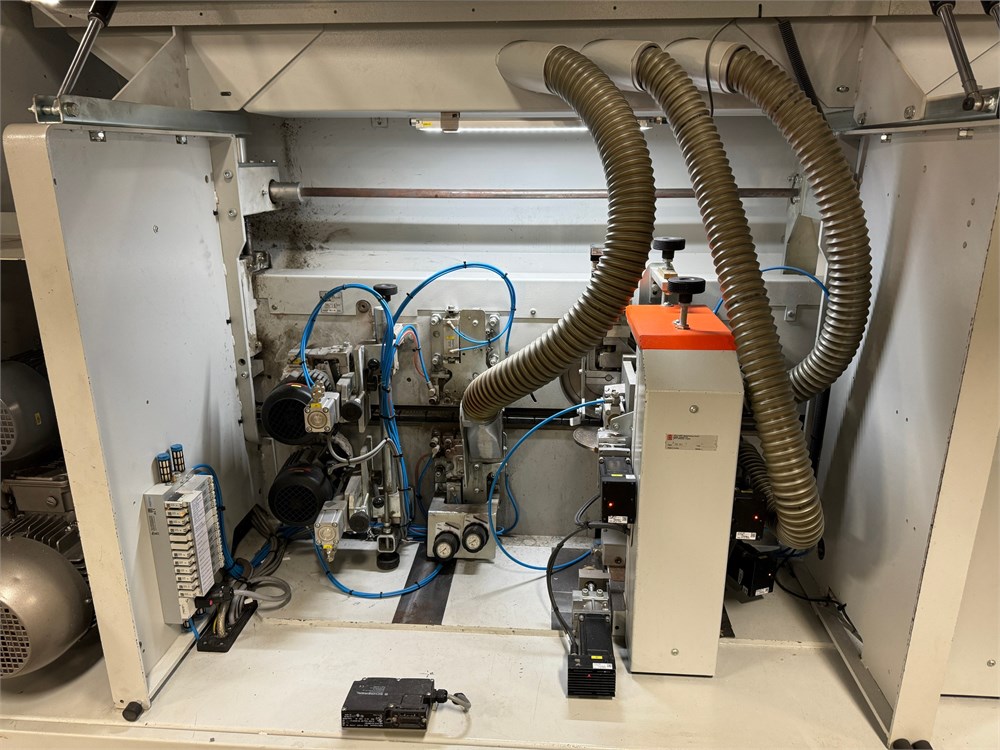

Holz-Her “Accura 1554 4.0 Auto” Automatic Edgebander

Edge thickness min./max. 0.4 – 3 mm (0.02 – 0.12″) for coiled material, 8 mm (0.315″) max for strips.

Panel thickness 8 – 60 mm (0.315″ – 2.36″); workpiece width min. 60 mm (2.36″); workpiece length min. 140 mm (5.5″); Feed speed 10 – 20 MPM (33 – 66 FPM).

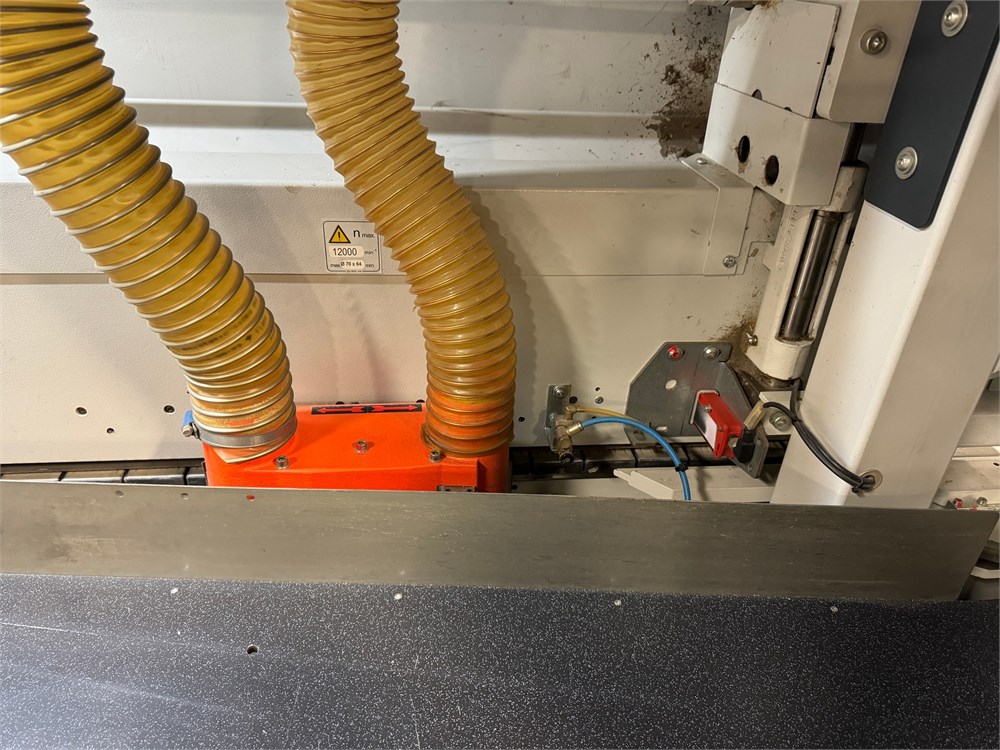

Pre-Milling Station “1802”: 2x 1.2 KW (1.6 HP) – 12,000 RPM motors.

Edge Magazine “1901”: for coil and strip processing, utilizing motion detector to ensure accurate, trouble-free positioning of edge material; exclusive “Tractor-Belt feed System”, edge guide equipped with automatic guillotine lock-out for safety, 3° approach angle allows easy feeding of solid wood edges.

Pressure Section: (1) large driven (synchronized with feed-speed)roller and (3) cantered idle rollers, servo adjustment.

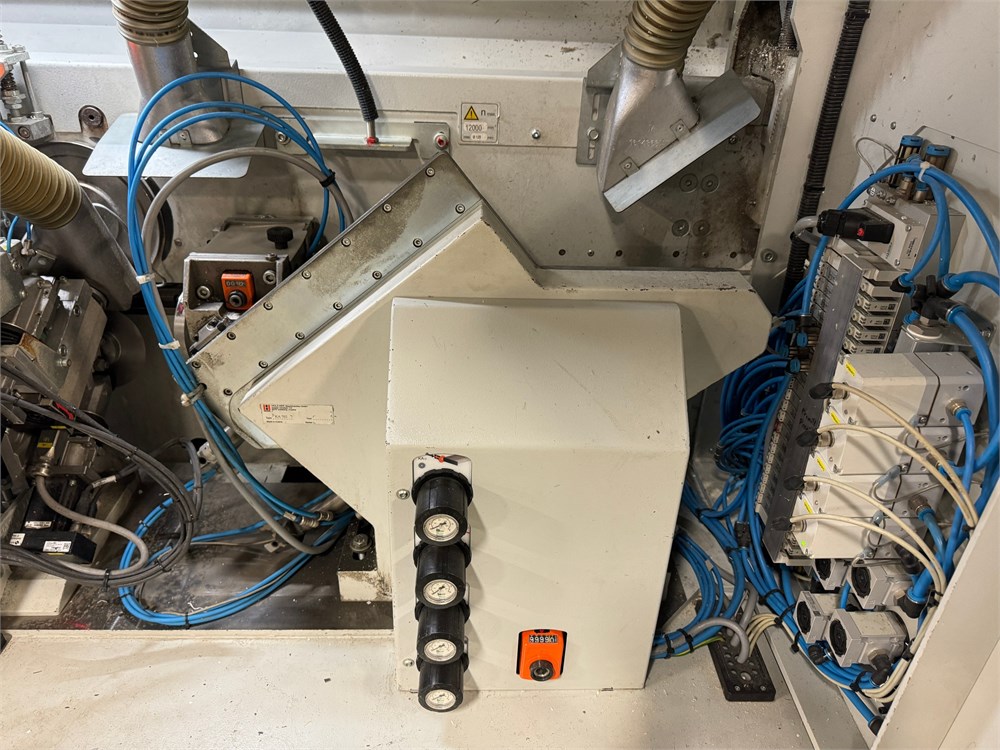

GLUING SYSTEM “GJ 301” (Glue Jet)… Processes “EVA” or “PUR” Glue in Cartridge.

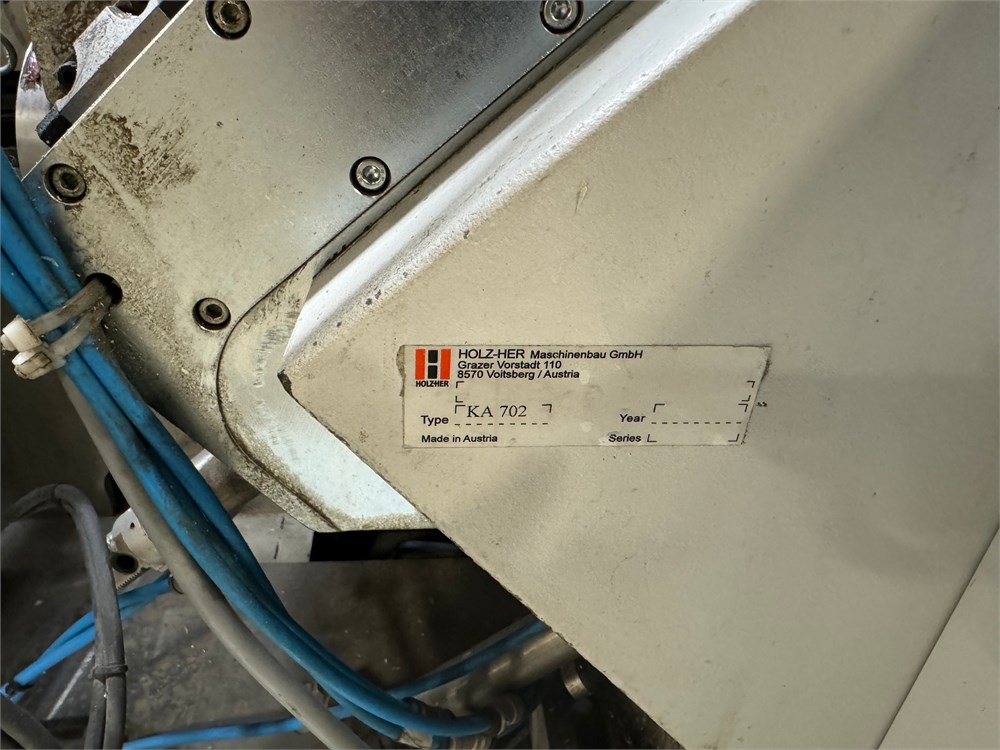

End Trimming Unit “KA 702″: Front & rear 2 x 0.45 KW (0.6 HP) – 9,000 RPM motor each, uni-point swivel-axis for no re-indexing when changing from flush to bevel end trim (0° – 10° bevel),”PCS” programmable pneumatic change-over from flush to bevel.

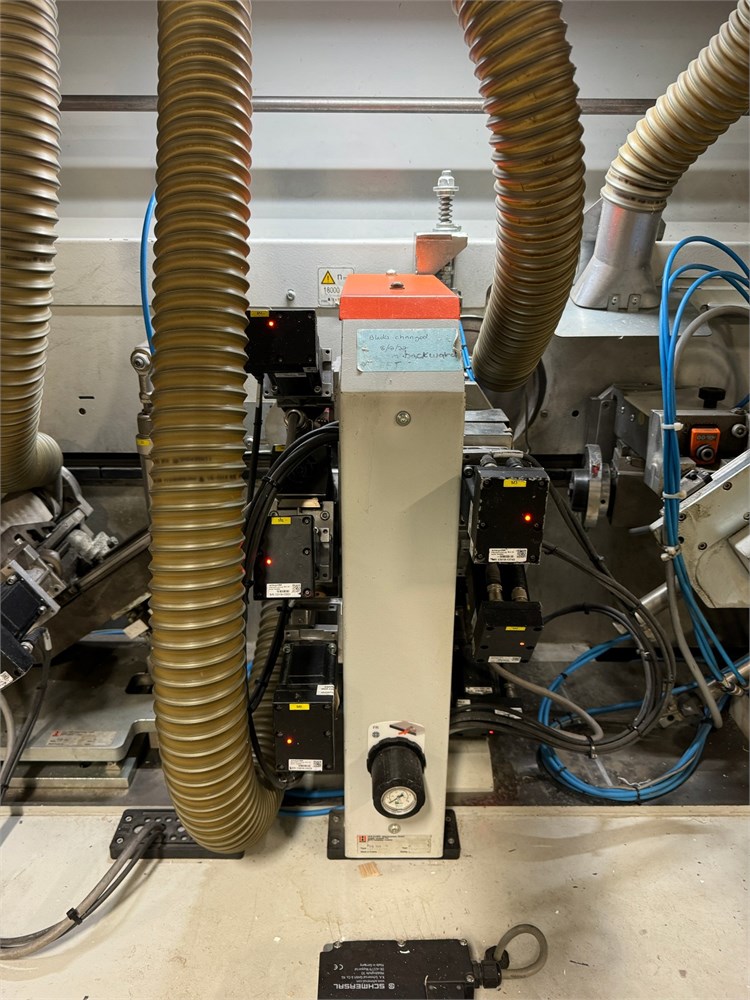

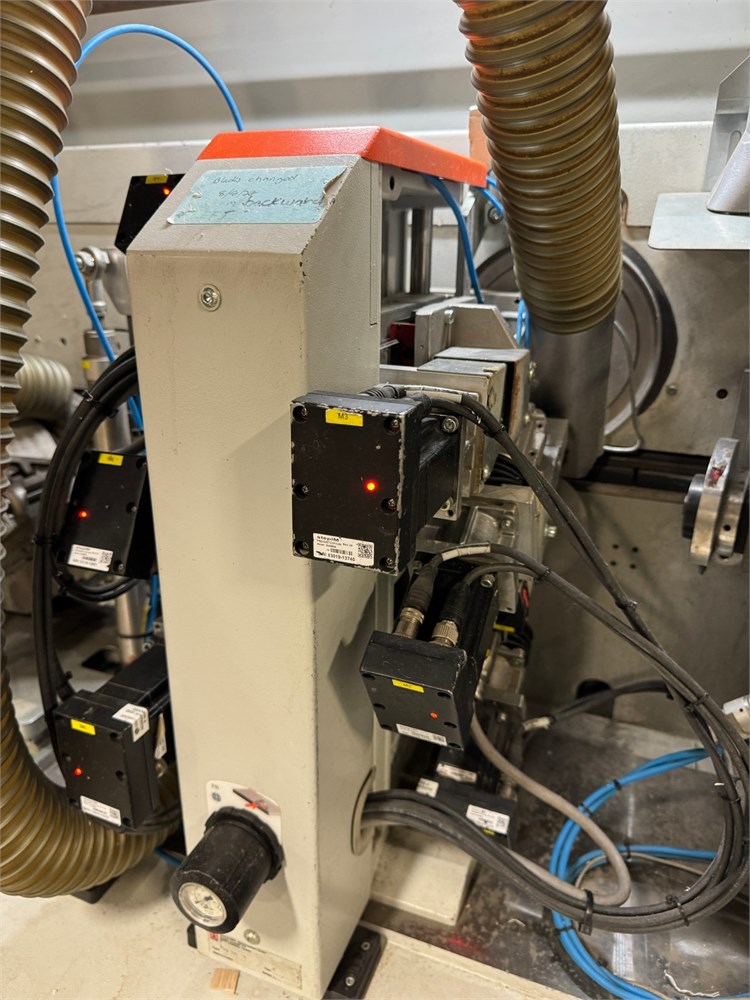

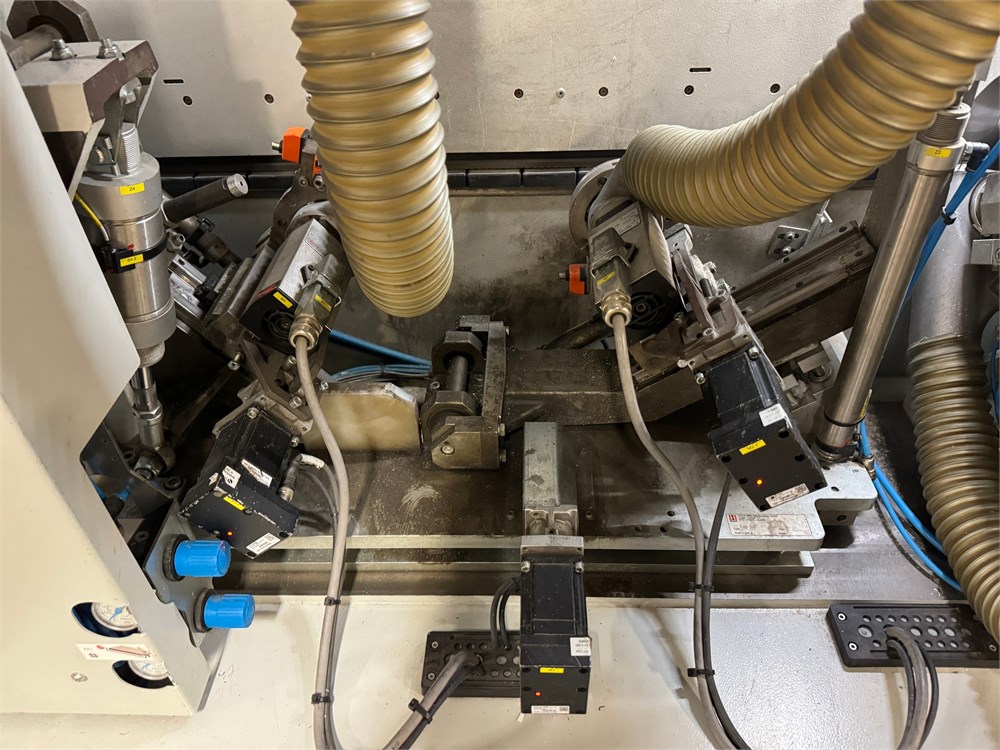

Flush/Bevel/Radius Combination Trimming Unit “FR 701”: Flush 6 mm, radius 3 mm trimming, servo controlled, 2 @ servo motors (1) for horizontal copy wheel & (1) for tool spindle position) programmable top & bottom unit 2 x 0.65 KW (0.88 HP) – 12,000 RPM each motor.

Uni-Point design with no second adjustment, pneumatic, programmable tilt action for changing the degree of bevel, digital counters for vertical copy wheel position and pneumatic air cylinder for in/out pre-positioning of trimming motor.

Corner Rounding Unit “FF 701″: (2) Motors 0.22 KW (0.30 HP) – 9000 RPM for up to 3 mm edge thickness and work-piece thickness min./max. 12 -60 mm (0.473 – 2.362”), max. feed speed 10 MPM (33 FMP).

Profile Scraping Unit “ZK 501″: Top/Bottom, servo motor controlled/programmable knife position, vertical copy wheel adjustment with quick setting spindle.

For PVC edges, reversible insert carbide knives, equipped with air-jet blowers and chip collector box.

Glue Scraping Unit ” FK”: Flat surface, top/bottom, ball bearing guided and pneumatic controlled. Reversible – replaceable knife inserts and blow-off nozzles.

Buffing Station: Top & bottom, 2 x 0.09 KW (0.25 HP)buffing motors with 150 mm ( 6.0″) cloth buffing wheel diameter.

Adjusts in any direction (vertical tilt is 0° – 5°, horizontal swivel is 0° – 20°); 1,440 RPM wheel rotation.

“EDGE CONTROL TOUCH” offers self-explanatory, graphic pictograms for simple user guidance. 18.5″ TouchScreen, with Brilliant graphic display of machining processes. Simple operation & ndash; rotating and swiveling control panel at eye height.

Pick Up Location

Thompsontown, PA

Make

HolzHer

Model

Accura 1554

Serial Number

251/1 911

Year

2019

Phase

3 PHASE

Voltage

230 VOLT

Buyer Inspection Period

March 12 and March 13, 2025 (9 am – 3 pm) or by appointment

Load Out Period

March 24 – April 7, 2025 (by appointment) unless other arrangements made in advance

Estimated Dimensions

4′ x 25′ x 6′

Estimated Weight

6,000 Lbs

Seller Comment

A rigger is required. Buyer’s Responsibility for Break-down, loading and removal.

Load Fee

Lot Notes

page views

515